One Huge Location, with Two Installed Destinations

Due to the rapid growth, Daimler Trucks Perth desperately needed a new, larger workshop to accommodate their client servicing, preparation and maintenance needs. Looking for speed, efficiency and most importantly space, Daimler turned to Levanta to deliver.

Project Challenge

Increased sales and the associated growth in their service division meant that Daimler Trucks Perth needed to expand their sales and service centres to cope with the increased workload. This realisation presented Daimler with a unique opportunity to relocate some of their existing workshop and install new equipment to a brand new, purpose built facility. Enhancing their capabilities, Daimler Trucks expanded their brand new premises to include a new pre-delivery centre, increased office and yard area, plus an additional servicing and maintenance workshop. Their goal for the new Hazelmere WA Truck Centre, was to create one of the largest and most advanced service facilities in Australia.

Our Solution

To ensure that they made the right decision when it came to workshop equipment, Daimler put their trust in Levanta to provide them with a reliable and lasting solutions to fit their needs and budget. We worked directly with the Dealer Principal, in conjunction with architects, builders and internal systems networking teams, to deliver this benchmark project. Manufacturing unique equipment specifically for the space, supplying heavy duty equipment and designing with the best space to productivity principles for higher throughput and enhanced flow, the two workshops were delivered on time and on budget; delivering the modern showroom appearance requested by Daimler Trucks.

The project required the supply and install a range of workshop equipment to best fit the needs of the client, including:

- 2 x BM Autoteknik In-Ground Roller Brake Testers with Shaker Plates

- 1 x 18t BendPak 4 Post Hoist with extended approach ramps

- 4 x 6t BendPak 4 Post Hoists with extended platforms

- 2 x Relocation of BendPak 4 Post Hoists

- 5 x AC Hydraulic 10t Air Hydraulic Single Ram Pit Jacks

- 1 x AC Hydraulic 10t Ait Hydraulic Twin Ram Jacking Beam

- 4 x AC Hydraulic 2.6t Air Hydraulic Jacking Beams

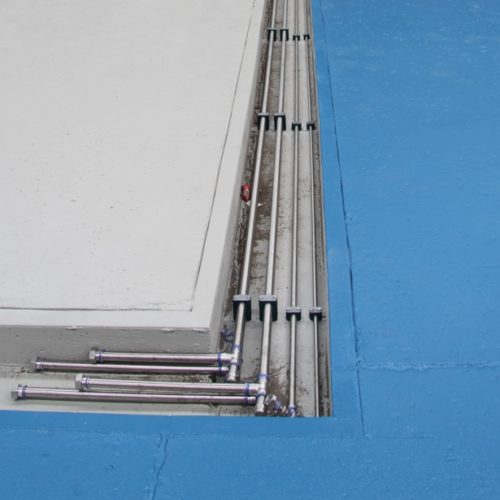

- Fully reticulated oil delivery system connected to hose reels shared between service bays

- Graco Matrix Fluid Management System

- Bulk Oil Storage Tanks

- Compressed air system with compressor package

Client Benefit

This heavy vehicle workshop fit-out project has exceeded the client brief and expectations. Delivering on our promise of a benchmark facility, Daimler’s new premises has been built to deliver increased capabilities, more efficient throughput, clear and effective flow principles, as well as increased productivity and profitability. Allowing more trucks to be prepared, serviced and maintained through the upgraded service capabilities has delivered an increase in sales, happier customers and growing revenue for Daimler Trucks Perth.

Get in touch with us today

Our expert team will be happy to answer any question you have, or provide you with an estimate